DIY BLOG - The front rooms

Being based in Dunfermline and travelling up to Skye for only a few days at a time is far from ideal when you have the drive to actively renovate a property. Such is the reality of life and it’s not uncommon for people to take years to renovate their property, especially when doing so themselves. After a few months hiatus from working on the main space, I came back up to to the property to find a large swathe of mold had taken over the walls of the front rooms. Since this was where I, or anyone masochistic enough to help me, would often sleep on visits, there wasn’t any other viable option than to strip the linings and get to the root of the issue.

There are a few problems I knew of that can cause this issue: When my granny lived here, she relentlessly heated the house to within an inch of its life - and probably had a shamefully huge carbon footprint doing so - however, this kept most (or at least the worst) of the damp at bay; I soon discovered there was no ventilation under the suspended timber floor - this was problematic as rising damp from the bare ground had no where to go but sit and stagnate but this was less of an issue as the floors weren’t insulated, so any temperature gradient was gradual meaning less chance of condensation; the main issue I found however were two rhone pipes happily ploughing the ground at the external corners of the rooms with all the rainwater from the pitched roof which was then quite literally being sucked back up the masonry and into the property.

These were all such fast growing problems that I decided to hold off on progress to the main space and begin another task of stripping out. Why stress about one job when you can stress about two..?

The plan was to keep the layout relatively simple - even as a young kid, the arrangement of the rooms, especially the entrance to each, always felt confused… looking at the plan below you can see if people were to exit each bedroom at the same time, they would be trying to occupy the same space. Very strange. In rearranging the layout I held two principles: have a generous hall space - it doesn’t need to be purely functional or reduced to the minimum but it can be a place where people can bump into each other and chat; accept that you can have one nice double bedroom and one smaller, single room - as I planned to fit insulation, this would mean losing 100mm around the perimeter so I decided to embrace this.

The original plan on the left - this extension was built sometime in the late 1950’s when an indoor toilet was first introduced into the croft house. The entrance to both bedrooms shares the same 800 x 800mm space and felt really weird. When updating the layout I wanted to have a more generous hall space and create ‘recesses’ for the door area so it didn’t feel like the door was intruding upon the usable floor plan. The bathroom, renovated a couple of years earlier, remains as it is - though it would benefit from insulation, I couldn’t bring myself to pull it apart… at least not just now.

The existing construction is suspended timber floor resting on an escarpment to the inner masonry leaf with a small cavity between that and the outer masonry leaf. I decided to retain the existing timber joists and make reparations where they were rotten. In retrospect, I wouldn’t do this again as they were so far off the level, it meant I had to cut new linings to take this into account and made the whole experience a little annoying. That said, because I was retaining the bathroom area, there really wasn’t much of an alternative… keeping the existing bathroom probably saved me a good bit of time - if it isn’t horribly broken and miserable, learn to embrace it.

Running heating pipes - in this case hep2o - can be a love/hate job. In many ways hep2o is incredibly easy to use any reasonably fail-safe when it comes to getting the heating working. I’m pretty sure that opinion would separate the plumbers from the DIY’ers as ideally, copper would be used everywhere… but again, I only have the skills I have so hep2o it is all the way. Annoyingly, I didn’t fit the netlon correctly - the mesh fabric used to hold the wool insulation between the joists. Ideally, this is draped over the top of the joists and stapled into position but here I literally stapled it to the underside of the joists so if - and when - the stapes eventually corrode, the insulation will sag like the proverbial… something to keep an eye on. Some other faults I would later discover, include not addressing the lack of underfloor ventilation - more of that pain further down the line…

Rebuilding is always the most fun part - getting a solid floor deck down is good for morale as well as having a clean surface to work from. Timber stud work goes up so quickly and gives an instant impression of space. It’s also a nice stage where everything is open and you know it will eventually be lined out and cellular - there’s something special about being a part of the space when it’s disparate and seeing it take the form that will be more familiar to others who occupy it. It’s really quite an intimate experience renovating a home to this degree.

For insulating and lining the walls, I had to strap them out with treated timber battens, ensuring they were plumb and square (note - the walls weren’t) and then drill them into the concrete with concrete screws for a solid fix

50mm PIR insulation was then screwed into the battens - I didn’t want to fit too much insulation, thereby reducing the size of the room more or separating the thermal envelope from the construction one by too much. I feel it’s a balance when renovating homes to not treat them like a new build

Once the insulation was in place - a very satisfying stage - every joint is taped before fitting battens to the lower portion. I had planned to line the bottom half in tongue and groove flooring whilst fitting OSB sheet to the upper half. Whereas the OSB could be fitted directly on top of the insulation, I introduced a service void on the lower half by using the additional battens and forming a route for electrics as well as allowing for the depth of the back boxes

Once I began on the tongue and groove, it was a matter of ensuring the cable runs were in place and that any holes were formed for back boxes - here you can see a cool circular hole for a European style bakelite switch

I wanted to try and retain an element of the traditional within a new and modern contemporary setting - the house is fundamentally old and of the crofting era but it needs to adapt to modern living. I think the balance of the monotone and retro aesthetic, against the modern OSB texture, works quite well.

Linings… The lower level of tongue and groove flooring took some time as each board was secrete nailed using a brad nailer for floors… sideways. I also had to allow for the wonky floor so each few boards I had to change the length of the cut. The OSB went in easily enough and I fitted it so that the height from the top of the tongue and groove to the ceiling would be 1.2m meaning I didn’t need to chop the OSB down. I wanted to finish the top of the tongue and groove with a solid piece of timber, so ripped down a length of flooring to get a continuous ‘dado’ border… saying that makes me cringe at the thought of employing a dado but I’m really glad with how it turned out.

Lining a ceiling solo with full sheets of OSB was… interesting. I formed a prop of sorts to allow me to wedge it onto the ceiling and shuffle it into place. I strapped off the underside of the insulated rafters with treated timber battens to ensure the ceiling was level (learning from my floor error) and consistent across the two rooms and hall and set about fitting the OSB so all joints were symmetrical. Unbeknownst to me at the time, I was suffering from Covid but pushed on regardless, wondering why I felt so ‘out of it’…

Installing the loft ladder was good fun, albeit a bit of a head scratcher trying to get the rafters parallel and the aperture just right. The addition of the OSB onto the hatch cover really helps it disappear when it’s closed.

I really do prefer minimal details and the house was replete with cheap architraves to windows and doors and it drove me mad - it was such a cluttered house in terms of content and character… but I don’t completely disregard all that - part of the character was what I loved growing up. I think my design aesthetic is to create areas of blank canvas to invite someone or something else to make its own mark. I also generally believe that architraves are needless ornamentation and hide poor workmanship - so a clean MDF box it was! Ideally, I would replace the windows if the budget would allow - these are pretty ugly brown uPVC casements… but after 15 years they actually work well so they are kept for now and probably will have handles upgraded.

Every time I come up to the house I work every hour I can during the day and then during the evening I work on my clients’ jobs. I never really take the time to visit my neighbours, wandering around the croft or head down the the shore, which is a bit crazy but I feel my time is so restricted, I can’t not work all I can. Occasionally, I will take a moment to enjoy the peace and serenity of the croft - the changing light throughout the day and season, the cloud formation, the sunsets, the dark skies and satellites flying overhead. It is one of the most magical places I can be.

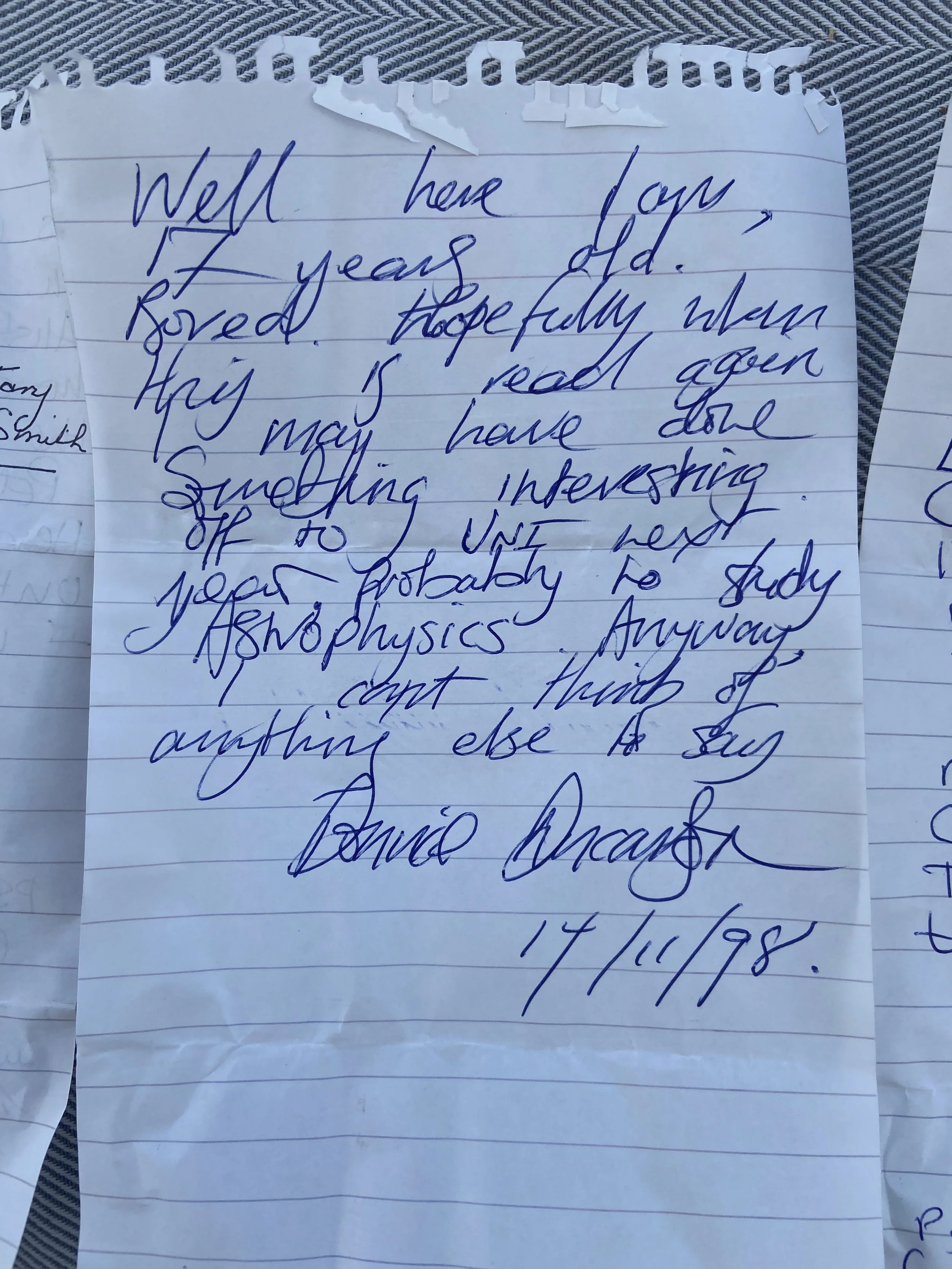

Some finds along the way: Shock journalism from the Highland News of 2012; Wallpaper design hidden behind radiators; A time capsule from 25 years ago, 14/11/98; Signature from my namesake - great uncle Donnie, 30/12/1952

It’s probably a pretty obvious thing to say that fitting the finishes is the most satisfying part of the job - maybe much like saying the final note in a piece of music is the best part because you’ve heard it all and can appreciate it in it’s entirety (Alan Watts would be aghast) but it is true to a degree and especially when you move past the surface level. The use of the monotone palette and soap and lye on the pine, gives a modest, restrained yet expressive feel to the rooms. The OSB walls are sheer but broken up by their random patterns of differing chip shapes and sizes but will also do well in giving a backdrop to any picture frames that go up.

The images below are a fairly quick example of the finished article(s), somewhat gilded with soft focus for some reason but I guess that fits the aesthetic. They are cosy - it’s a bit of a novelty that the rooms can hold their heat and often when working in the cold, unheated part of the house, I’ll head to bed for the night into what feels like a different house… growing up, that kind of contained warmth was not even a thought and the best you could do was a water filled ‘pig’ or latterly, an electric blanket to provide a modicum of localised heat to an otherwise damp bed. Insulating the heating pipes means that the radiators heat up almost instantly, ensuring the heat is delivered to the rooms and not under the floor.

SOMETHING TO CONSIDER…

…as an appendix to the above finished construction, I was still aware the solum required ventilation however in my haste to rebuild, I somewhat stubbornly neglected to address this issue until the rooms were finished. Once I realised the issue desperately needed to be addressed, I attempted to core holes for ventilation through what I discovered to be a circa 400mm thick poured concrete sub wall. I was about halfway through with my SDS drill and ‘diamond’ coring bit before the drill burnt out and I realised I was going to have to rethink my approach. SDS drills explicitly state they are not suitable for coring and most of the time it seems I know better - but this time, it was clear I would need to get a much better bit (specifically for coring dense concrete) and hire a coring drill. Once I got hold of both of these (hiring the latter from Speedy - a Hilti monster that cut through concrete like butter) I was able to core with not only ease, but actual pleasure.

Since then, there have been no further condensation issues and the insulation between the floor joists is bone dry. Regardless, the video opposite should serve as a stark reminder to the potential issues where ventilation is not available to carry away water condensing on the underside of insulation.

The irony to all this is that the reasons for stripping the front rooms was because of a lack of ventilation and condensation turning to mould. The warm air trapped under the floor was unable to vent, resulting in moist air becoming trapped there and condensing on the cold side of the insulation.

This is the uglier side to renovation - making mistakes. It’s not fun, you feel foolish for not doing a job properly or researching sufficiently (or at all), and it’s enough to make you wonder if you should be doing what you’re doing. For me, it’s my heuristic approach to learning, which is getting better as I go but I do tend to throw myself into things, if I don’t hold back and take seven breaths to contemplate…